Projekt

Covid-19-Testzentren

Kunde

Ministerium für Gesundheit und Soziales/Crown Commercial Service

Auftragnehmer

Premier Modular

ZEITPLAN

2 Standorte pro Woche im gesamten Vereinigten Königreich

Umfang

50 Testzentren

BAULÖSUNG

Temporärer Bau

DIE KUNDENPERSPEKTIVE

PRESSESPRECHER, CROWN COMMERCIAL SERVICE:

“In dieser unglaublich schwierigen Zeit hat der Offsite-Sektor definitiv einen Gang höher geschaltet – einerseits, um die Regierung bei der Krisenbewältigung zu unterstützen, andererseits, um kritische Bauprojekte des öffentlichen Sektors sicher voranzutreiben.“

“Wie unsere Hauptlieferanten die Schwierigkeiten, die mit dem Errichten des Covid-19-Testzentrums einhergegangen sind, gemeistert haben, war sehr beeindruckend. Zu Beginn der Pandemie wurde der Betrieb auf den Baustellen im ganzen Land eingestellt; hinzu kam das Gebot des Social Distancings, das die Produktivität zusätzlich reduzierte. Die Offsite-Betriebsstätten blieben aber in Betrieb und Spezialisten wie Premier waren auch weiterhin ausgelastet, bauten ihre Mietflotte aus und stellten neue Mitarbeiterinnen und Mitarbeiter ein, um die Nachfrage zu befriedigen. Dies wird sich langfristig positiv auf den Covid Recovery Plan des Vereinigten Königreichs auswirken.“

GEORGE SWANEPOEL, PROJEKTMANAGER BEIM TEST-SERVICEANBIETER SODEXO:

“Die Einrichtung des Standorts und der Testanlage in Havant lief einfach fantastisch ab. Das Gebäude war gut durchdacht – der Strom der Patientinnen und Patienten, die zum Testen kamen und dabei Abstand halten mussten, wurde äußerst effizient geleitet. Die modulare Lösung war leicht zu reinigen, war nicht den Elementen ausgesetzt und bot unseren Mitarbeitenden eine sichere und komfortable Arbeitsumgebung. Das Gebäude war in wenigen Stunden errichtet. Dieses Testzentrum hat die Gemeinde hier vor Ort wirklich nachhaltig positiv verändert.“

DIE KUNDENVORGABEN

Um die Regierung dabei zu unterstützen, die Testkapazitäten während der Corona-Pandemie in kürzester Zeit zu erhöhen und die öffentliche Gesundheit zu schützen, mussten im gesamten Vereinigten Königreich kommunale Testzentren errichtet werden.

DIE HERAUSFORDERUNGEN

- Seit dem ersten Projekt in Bolton hat Premier eigenständige kommunale Testzentren in Städten im ganzen Land eingerichtet, darunter Glasgow, Leamington Spa, Dudley, Nottingham, Aylesbury, Buxton, Bury St Edmunds, Torbay, Lambeth, Durham und Liverpool.

- Die geografische Verteilung der Standorte erforderte eine effiziente Logistik und ein sorgfältig geplantes Projektmanagement.

- Die maßgefertigten Testgebäude wurden jeweils auf Bestellung hergestellt. Um dies zu ermöglichen, setzte Premier in seiner Produktionsstätte in East Yorkshire eine ganze Extraschicht ein und arbeitete auch nachts durch. So konnte das Unternehmen die Rekordvorlaufzeiten erreichen, die für diesen Auftrag und andere Großprojekte während der Pandemie erforderlich waren.

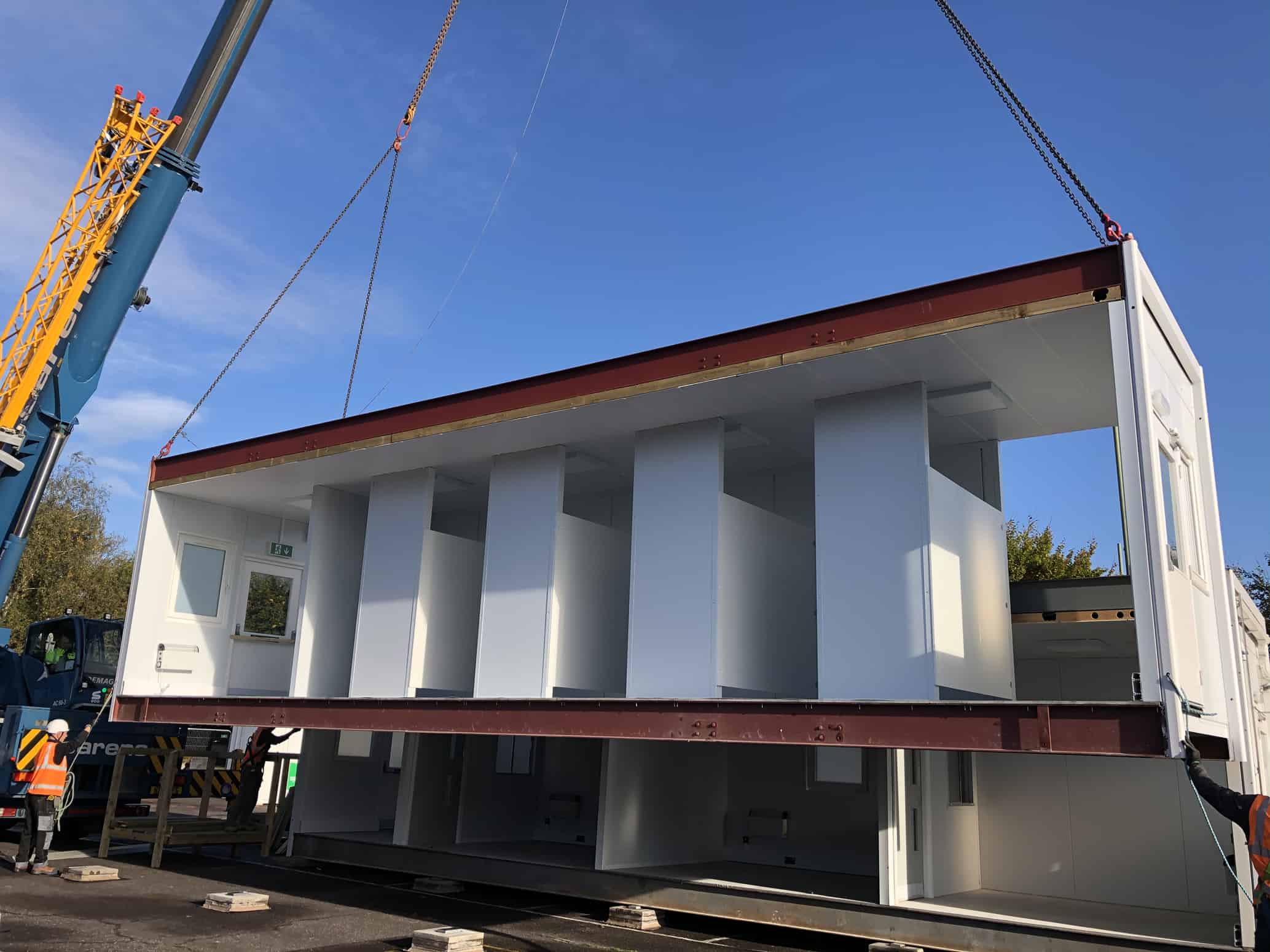

- Um die Installation von etwa zwei Standorten pro Woche zu realisieren, brachte Premier eine Reihe sehr engagierter und zuverlässiger Lieferanten zusammen. Die Vorlaufzeit von der Ankündigung bis zur Übergabe konnte auf eine Woche reduziert werden, an manchen Standorten sogar weniger – eine phänomenale Leistung!

- Premier verkürzte die Standortinstallation auf nur drei Tage, einschließlich Tests, Inbetriebnahme, Serviceanschlüsse, Übergabe und Einweisung. Andere Anbieter von Testzentren brauchten im Schnitt fünf Tage.

- Einige innerstädtische Standorte waren sehr beengt und erforderten daher eine sorgfältige logistische Planung, um klug mit dem begrenzten Platz umzugehen, insbesondere während der Errichtung.

Die Offsite-Lösung

Der mit mehreren Millionen Pfund dotierte Auftrag, den Premier über den Crown Commercial Service für das Ministerium für Gesundheit und Soziales erhalten hat, umfasst 50 Testzentren im ganzen Vereinigten Königreich, von Portsmouth bis Inverness.

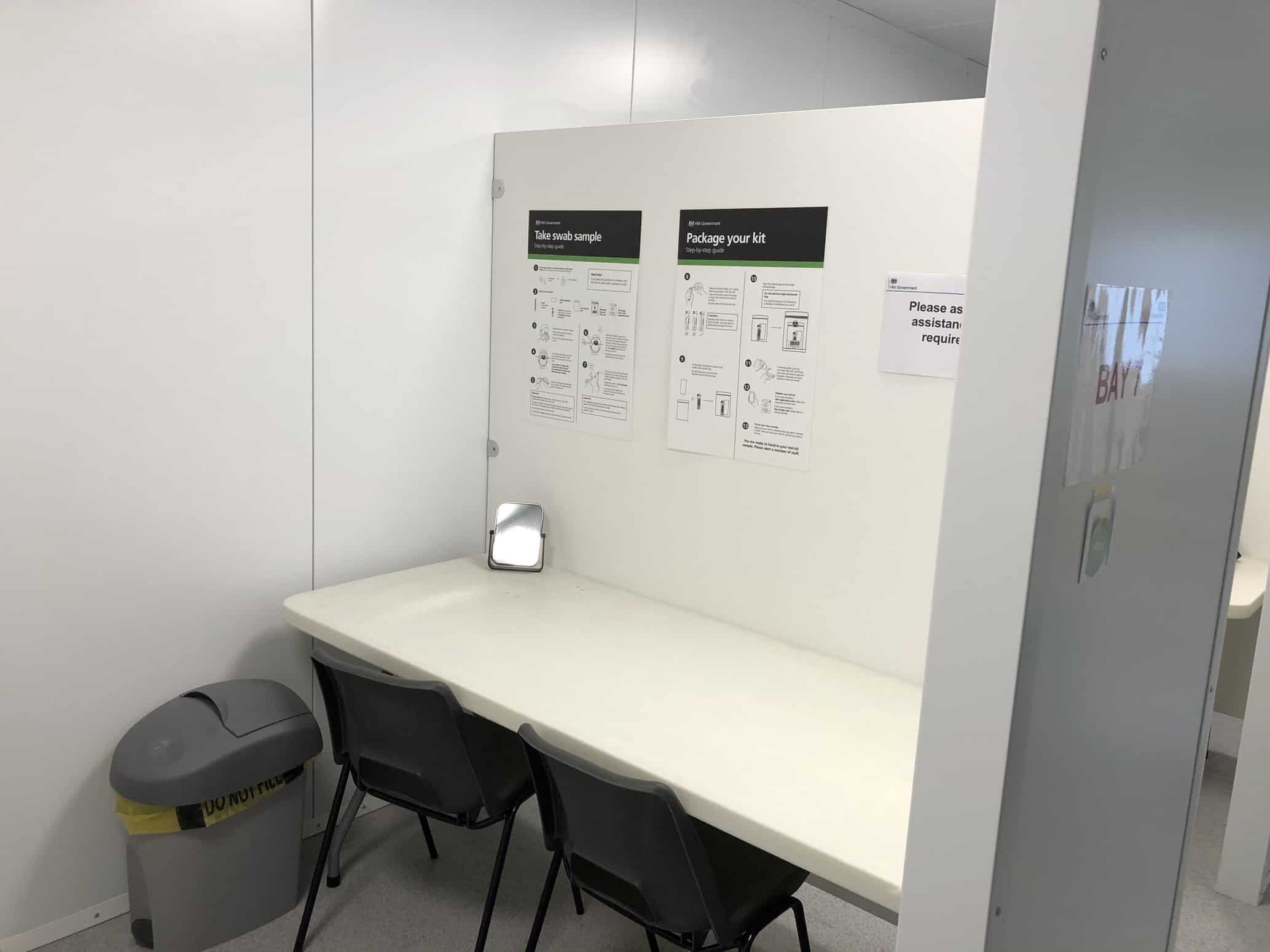

Jeder einzelne Teststandort verfügte über ein 110 Quadratmeter großes, zweckmäßiges Testgebäude, das mit acht Patientenkabinen, Hygienetrennwänden, einem separaten Ein- und Ausgang für das Personal, Bereichen für die Testabnahme und -abgabe sowie einem Familien-Testraum ausgestattet war.

Der Auftrag beinhaltete die Bereitstellung von Gemeinschaftseinrichtungen in drei Gebäuden, in denen ein Raum für persönliche Schutzausrüstung, ein Lager, ein Raum für die Testvorbereitung, ein Ruheraum für das Personal, eine Teeküche und Toiletten untergebracht werden sollten, sowie die Bereitstellung von essenziellen Vorrichtungen – Wasserversorgung, Abwassersammlung, Datenkommunikation, Alarmsysteme und Stromgeneratoren.

Darüber hinaus realisierte Premier auch die Umzäunung des Geländes, Fundamente, Treppen und Rampen, Flutlichtanlagen, Funkkommunikation und Datensätze und die tägliche Wasser- und Abwasserentsorgung an jedem Standort.

ABSTANDHALTEN IN EINER WERKSUMGEBUNG

Es ist hinlänglich belegt, dass eine modulare Bauweise mehr Sicherheit, ein geringeres Risiko und eine größere Zuverlässigkeit in puncto Zeit- und Budgeteinhaltung bietet. Die Tatsache, dass die Werke von Premier seit Beginn der Pandemie im März 2020 weiterhin sicher und mit voller Kapazität gearbeitet haben, ist ein klarer Beweis dafür.

Abstand lässt sich deutlich einfacher in einer kontrollierten Werksumgebung einhalten als auf einer Baustelle. Und für Bauunternehmen, die während einer Pandemie arbeiten, ist es von großem Vorteil, ihre Belegschaft auf der Baustelle reduzieren zu können.

Premier hat während der Pandemie rund 100 neue Mitarbeiterinnen und Mitarbeiter eingestellt, weil die Nachfrage nach den temporären Modulen und den maßgeschneiderten Offsite-Konstruktionslösungen des Unternehmens so stark gestiegen ist.